In the current era of personalized customization and brand promotion, hats are not only fashion items, but also an important carrier of corporate image and team spirit. However, the traditional single heat plate hat press is often difficult to balance uniform heating and accurate alignment when dealing with hat transfer, which affects the final transfer quality. The versatile dual heat hat press offers a revolutionary solution for the fine transfer of embroidery patches and badges with its dual heating system, independent temperature control and 360-degree transfer function. This article will explore the advantages, technical specifications, application scenarios and operation skills of the equipment, to help you easily master the hat transfer technology, to achieve efficient and professional customization effect!

It is a high-end heat press machine designed for hat transfer. The device uses a dual heating system with independent upper and lower plate temperature control to ensure uniform heat transfer during the transfer process. Whether it's embroidery patches, badge transfers, or other custom processes, this machine meets high quality, precise transfer requirements and is ideal for professional hat customization, branding, and personalized small batch production.

Model | CP2815-3 Pro |

Features | Semi-auto | Hat | Dual Heat | All-in-One Platen |

Voltage | 110V - 60Hz | 220V - 50Hz |

Heat Platen | 9.5 x 18cm |

Power | 600W |

Controller | LCD Controller V4 |

Max. Temp. | 210℃/410°F |

Temp. Difference | ±4°F/2℃ |

Power-off Preset | Max. 120 Mins |

Max Timer Preset | 999 sec. |

Max. Downforce | 250 g/cm² |

Pressure Setting | Hand Wheel |

Accept Thickness | ≤1cm |

Product Size | 49.7 x 48.5 x 30.8cm |

Package Size | 59 x 33 x 53cm |

Product Weight | 20kg |

Shipping Weight | 26kg |

Certificate | CE/UKCA (SGS Audited) |

Independent temperature control system:

The upper and lower plates are independently controlled to ensure accurate temperature management and effectively avoid transfer defects caused by local overheating or temperature difference.

360°degree transfer:

The design supports the front and back of the hat and the side of the transfer, so that your pattern without dead corners, improve the efficiency of customization and product beauty.

Automatic open protection design:

The magnetic semi-automatic opening mechanism can effectively prevent overpressure or overheating, and protect the cap type from damage.

Laser Alignment Assist:

A built-in laser alignment system helps you precisely position the patch or badge to ensure that the pattern is perfectly centered.

Precise digital display:

Real-time monitoring of transfer time and temperature, multi-timer setting make operation easier and ensure stable and efficient transfer.

A variety of hat pads design:

equipped with a variety of hat pads , can be used for truck hats, baseball hats, fisherman hats and other hat types, to meet different product needs.

Special silicone auxiliary pad:

Effectively prevent fabric wrinkles and scorch marks, to ensure that every transfer to achieve perfect results.

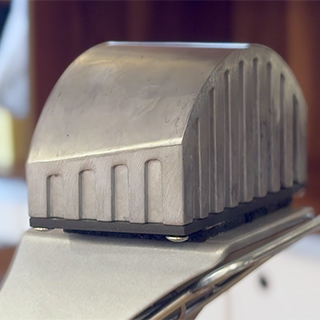

Cast aluminum structure:

The rugged cast aluminum frame not only optimizes heat distribution, but also reduces energy consumption, making it suitable for long periods of continuous operation.

Adjustable pressure control:

Flexibly adjust the pressure according to the cap type and material to ensure high-quality transfer without distortion.

![]()

The all-purpose dual hot cap press supports a variety of cap types, including but not limited to:

Baseball cap: Classic style, suitable for a variety of transfer processes.

Truck cap: Wide front plate for large area patterns.

Fisherman cap: The material is soft, and the pressure should be adjusted appropriately when transferring.

Flat cap: suitable for street trend customization, pattern alignment requirements are high.

Golf hat: Customized brand LOGO, emphasizing precise positioning.

This machine supports a variety of transfer processes, commonly used materials include:

DTF (Direct-to-Film) : Suitable for full color pattern, excellent detail performance.

HTV (Thermal transfer film) : suitable for monochrome or multi-level design, the effect is eye-catching.

Embroidered patches: Add texture and layering to bring a unique style to the hat.

Silicone transfer: With wear-resistant and waterproof properties, suitable for sports caps.

Sublimation transfer: achieve bright and durable color effects, designed for polyester fabrics.

Crystal patch: Provides a shiny finish for high-end customization needs.

Successful hat transfer depends on precise control of temperature, time and pressure. The following are the basic parameters of common transfer methods:

Transfer material | Temperature(°C) | Time(S) | Pressure |

DTF | 150-165 | 10-12 | medium |

HTV | 150-165 | 8-12 | medium |

Embroidered patches | 150-160 | 20-30 | medium |

Silicone transfer | 150-160 | 20-30 | medium |

Sublimation transfer | 190-200 | 20-25 | medium |

Crystal patch | 150-165 | 10-15 | medium |

Note: Please test according to the specific material and design requirements, adjust the parameters to obtain the best transfer effect.

In order to ensure that the hat is closely fitted to the heating plate during the transfer process, the corresponding hat pad needs to be selected for different styles of hats to prevent poor transfer due to uneven contact.

Fashion brand: Offering limited edition bespoke hats to appeal to younger consumers.

Sports team: Produce uniform design of team uniforms and hats to enhance team cohesion.

Corporate promotion: customized hats printed with corporate LOGO for promotion and brand promotion.

Educational institutions: Make school uniforms or commemorative hats to meet the needs of campus customization.

Tourism souvenir: The production of special hats for tourist attractions as unique souvenirs.

Non-profit organization: Customized public welfare event hats to help with publicity and fundraising activities.

Step 1: Choose the right hat pad

According to the style and material of the hat, the corresponding hat pad is selected to ensure that the hat and the heating plate are closely fitted during the transfer process.

Step 2: Set parameters

According to the selected transfer material, adjust the temperature, time and pressure of the upper and lower plates to ensure that the equipment parameters meet the process requirements.

Step 3: Prepare the hat

Make sure the hat is clean, flat and free of dust or oil; If necessary, gently preheat with an iron to remove wrinkles.

Step 4: Place the design pattern correctly

Place the transfer pattern exactly on the hat, using the alignment tool if necessary to ensure that the pattern is centered and symmetrical.

Step 5: Start the transfer process

After closing the handle, the device automatically starts the countdown program and evenly applies heat and pressure; Dual hot plate design ensures consistent temperature throughout the transfer process

Step 6: Remove the transfer material

After the transfer is complete, choose cold or hot peel according to the requirements of the material used, and easily remove the transfer paper to ensure that the pattern is complete and no residue.

Step 7: Complete subsequent operations

Press lightly on the surface of the hat for a few seconds to enhance pattern adhesion and eliminate any bubbles or marks that may exist to ensure a perfect transfer.

Periodically check the device: Periodically check the power cables, control panels, and mechanical components to ensure the normal operation of the device and prevent potential security risks.

Strictly abide by the operation rules: Follow the instructions in the user manual to avoid equipment failures or transfer errors caused by improper operations.

Wear protective equipment: It is recommended to wear high-temperature gloves during operation to prevent burns caused by direct contact with high-temperature components.

Q1: What types of hats is this dual heated hat press suitable for?

A1: This machine is mainly suitable for baseball cap, truck cap, fisherman hat, flat brimmed hat and other hat types, but also suitable for some non-traditional hats.

Q2: What transfer processes are supported?

A2: The equipment supports a variety of transfer processes such as DTF, HTV, embroidery patch, silicone transfer, sublimation transfer and crystal patch.

Q3: What are the recommended temperature and time settings?

A3: Different transfer materials have slightly different parameters, such as sublimation transfer recommended temperature 190-200 °C, time 20-25 seconds; The specific parameters should be adjusted according to the test results.

Q4: How to ensure accurate alignment of transfer designs?

A4: It is recommended to use a laser alignment or alignment tool to ensure that the hat is correctly aligned with the transfer designs.

Q5: How to adjust the equipment pressure?

A5: It can be adjusted by pressure knob, it is recommended to test the pressure uniformity with printing paper first.

Q6: What if there are pressing marks or incomplete printing?

A6: Please properly reduce the temperature or shorten the pressure time, and check that the hat pad and silicone auxiliary pad are placed correctly.

Q7: Does the hat need to be preheated before hot pressing?

A7: It is recommended to preheat for 3-5 seconds to remove moisture and wrinkles in the fabric to ensure a better transfer effect.

Use high temperature cleaner and soft cloth to wipe the upper and lower heating plate regularly to remove ink and adhesive residue and maintain heat transfer efficiency.

Periodically check power cables, fuses, control panels, and internal mechanical components to ensure the normal operation of devices and prevent potential security risks.

The pressure regulating parts are regularly filled with high temperature resistant lubricating oil to maintain smooth operation and extend the service life of the equipment.

The temperature sensor in the temperature control system is calibrated regularly to ensure that the display data is accurate, thus achieving accurate transfer.

Strictly follow the manufacturer's recommended maintenance guide for daily operation, if necessary, contact professionals for regular maintenance.

The all-in-one dual heated hat press provides an efficient, accurate and safe solution for embroidery patch and badge customization with independent dual plate temperature control, 360-degree transfer and multiple cap holder designs. Whether you are a fashion brand, sports team or corporate promotion, you can use this device to achieve perfect transfer effect, improve product quality and market competitiveness. Choose this equipment, that is, choose the perfect integration of advanced technology and excellent quality, and jointly create a bright future of the hat customization industry!

For more product details, technical support or after-sales service, please visit our official website or contact our customer service team:

【E-mail】admin@heatpressleader.com

【WeChat | WhatsApp】+86 18659276806

【Home】www.heatpressleader.com

【Facebook】www.facebook.com/HeatPressLeader

【TikTok】www.tiktok.com/@heatpress_leader

【Instagram】www.instagram.com/heatpressleader