In the current era of personalized customization and textile printing market booming, the efficiency and quality of printing machine directly determines the competitiveness of products. Traditional heat presses often affect the sublimation printing process due to complicated operation, uneven heat distribution, etc., while some pneumatic machine requires additional air compressor, which increases the machine investment and maintenance difficulties. 16x20 pneumatic sublimation heat press machine (40x50cm) provides you with even, efficient and convenient sublimation printing solution with its pneumatic pressure system, swing-away upper platen and slide-out drawer. The solution is uniform, efficient and easy to use. In this article, we will analyze this machine in detail from introduction, technical specifications, advantageous features, application scenarios, operation tips and precautions, etc., to help you achieve stable and efficient printing production.

16x20 pneumatic sublimation heat press machine is a professional heat press machine designed for sublimation printing on polyester fabrics. The machine has a large heating plate of 40x50cm and adopts a pneumatic pressure system to achieve even and stable pressure through the cylinder. The unique swing-away upper platen design allows the upper platen to swing smoothly away from the lower platen for easy product placement and removal. At the same time, the machine is equipped with a slide-out drawer for better placement of clothes, silicone mats and auxiliary tools to optimize the workflow. The machine is suitable for sublimation printing on T-shirts, sweatshirts, sportswear and other polyester materials, ideal for professional customization, brand promotion and mass production.

| Model | B1-N |

| Features | Pneumatic | Slide Pro | Quick Platens |

| Voltage | 110V - 60Hz | 220V - 50Hz |

| Heat Platen | 16" x 20" | 40 x 50cm |

| Power | 1800W - 2200W |

| Controller | LCD Controller V2 |

| Max. Temp. | 232℃/450°F |

| Temp. Difference | ±4°F/2℃ |

| Power-off Preset | Max. 120 Mins |

| Max Timer Preset | 999 sec. |

| Max. Downforce | 500 g/cm² - 40 x 50cm |

| Pressure Setting | Air Regulator |

| Accept Thickness | ≤5cm |

| Product Size | 85 x 44 x 54cm |

| Package Size | 86.5 x 54.5 x 72.5cm |

| Product Weight | 66kg |

| Shipping Weight | 71kg |

| Certificate | CE/UKCA (SGS Audited) |

Pneumatic Pressure System, Uniform and Stable:

The pneumatic pressure system can provide continuous and even pressure to ensure balanced heat distribution during the sublimation printing process, effectively preventing pattern distortion caused by insufficient or excessive local pressure.

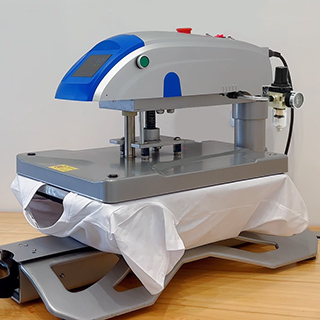

Swing-away design, convenient operation:

The unique upper platen swing-away design makes it easier to place, adjust and remove the T-shirt, significantly reducing the difficulty of operation and the risk of error.

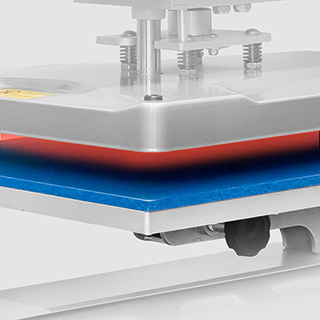

The function of slide-out drawer:

Its slide-out drawer design allows you to place clothes, silicone mats and related tools in a more convenient way, enhancing work efficiency and keeping your work area tidy.

Precise temperature control to ensure printing effect:

The machine is equipped with a highly efficient heating system, which quickly reaches the set temperature, and combined with precise temperature control technology, provides stable heat support for each printing, thus realizing vivid and long-lasting printing effects.

16x20 Pneumatic sublimation heat press machine is mainly suitable for sublimation printing on various polyester fabrics, widely used in:

Clothing printing: T-shirt, sweatshirt, sportswear, work clothes, etc.

Household products: canvas bags, cushions, aprons, mouse pads, etc.

Brand promotion: corporate culture shirt, promotional gifts, souvenirs, etc.

Personalized customization: fan peripheral, limited edition customization, school anniversary souvenirs, etc.

The machine mainly supports sublimation transfers, but is also compatible with some other heat transfer processes:

Sublimation Transfer: Designed for polyester fabrics to achieve vibrant colors and durable prints.

Heat Transfer Film (HTV): For some processes requiring localized transfers, but with adjustable parameters.

Special effect transfers: Can be partially customized to meet the needs of personalization.

Successful heat transfers depend on precise control of temperature, time and pressure. Below is a reference of the basic parameters of common transfer processes:

| Transfer Material | Temperature (°C) | Time (sec) | Pressure |

| Direct Transfer (DTF) | 150–165 | 10–12 | Moderate |

| Heat Transfer Film (HTV) | 150–165 | 8–12 | Moderate |

| Sublimation Transfer | 190–200 | 20–25 | Light to Moderate |

| Special Foil Transfer | 160–170 | 10–15 | Moderate |

Note: Specific parameters may be adjusted according to actual materials and design requirements. Please be sure to conduct trial printing and adjust the parameters first.

Step 1: Setting parameters

Set the temperature, time and pressure on the control panel of the machine to suit the selected transfer process.

Step 2: Place the product

Place the T-shirt, canvas bag and other products flat on the platen, make sure the pattern position is accurate.

Step 3: Start the heat press

After closing the operating handle, the machine automatically starts the countdown program to apply heat and pressure evenly; the swing-away upper platen ensures safe operation during the heat pressing process.

Step 4: Removing the transfer paper

At the end of the transfer cycle, remove the transfer paper according to the requirements of the transfer material (cold or hot peeling) to ensure that the design is fully attached to the T-shirt.

Step 5: Complete the subsequent processing

Re-heat press the pattern for about five seconds to strengthen the pattern adhesion and eliminate possible bubbles or marks to ensure perfect printing results.

Keep clean around the machine to avoid foreign objects affecting the contact of the heating plate

Wear high-temperature resistant gloves during operation to prevent burns caused by direct contact with the hot plate.

Regularly check the pneumatic piping and power lines to ensure the safe operation of the machine.

Shut down the machine in time after use and clean and maintain it regularly.

Use a high temperature resistant cleaner and a soft cloth to wipe the heating platen regularly to remove ink and adhesive residues to ensure heat conduction efficiency.

Inspection of pneumatic system and electrical components

Regularly inspect pneumatic piping, cylinders and power lines to ensure stable machine operation and prevent malfunctions.

Lubricate moving parts

Regularly fill the electric drive and pressure regulating parts with high temperature resistant lubricating oil to keep the operation smooth and prevent mechanical wear.

Calibrate the temperature control system

Regularly calibrate the thermostat to ensure an accurate temperature display to safeguard the results of each transfer.

Follow the manufacturer's maintenance manual

Strictly follow the user manual's recommendations for daily maintenance and regular inspections to extend the life of the machine.

Q1: Does the pneumatic system require additional maintenance?

A1: Regularly check the pneumatic lines and cylinders to make sure there are no leaks or wear and tear, and perform the necessary lubrication and maintenance according to the manufacturer's recommendations.

Q2: How to ensure accurate alignment of the transfer pattern?

A2: It is recommended to use alignment tools or laser alignment auxiliary machine to ensure accurate alignment of the transfer paper and the T-shirt.

Q3:What should you pay attention to when the machine is running continuously for a long time?

A3:Please check the status of the temperature control and pneumatic system of the machine regularly to ensure that the cooling system works properly and keep the machine clean to prevent dust or residue from affecting the performance.

16x20 Pneumatic Sublimation Heat Press Machine (40x50cm) is ideal for improving productivity and printing quality with its efficient pneumatic pressure system, swing-away upper platen and slide out design, which provides stable and even heat and pressure for sublimation printing on polyester fabrics. Whether you are a small personalized customized store or a large-scale mass production enterprise, this machine can help you achieve high-quality and high-efficiency printing results, help you stand out in the competitive market, and jointly create a bright future for the printing industry!

For more product details, technical support or after-sales service, please visit our official website or contact our customer service team:

【E-mail】admin@heatpressleader.com

【WeChat | WhatsApp】+86 18659276806

【Home】www.heatpressleader.com

【Facebook】www.facebook.com/HeatPressLeader

【TikTok】www.tiktok.com/@heatpress_leader

【Instagram】www.instagram.com/heatpressleader