In the era of personalized customization and fashion printing, a high-performance, accurate and easy-to-operate heat press is essential to achieve professional-quality garment transfer printing. Heat Press Leader's 16x20 electric heat press features advanced temperature and pressure control systems, large worktables, and intelligent digital control interfaces, fully meet the diverse needs of T-shirt printing and other textile transfer printing. This article will introduce the advantages, technical specifications and Operation Instructions of this advanced heat press to help you easily achieve high-quality transfer printing.

16X20 electric heat press is a high-end equipment designed for t-shirt printing and textile transfer. It adopts full digital control system, can accurately adjust the temperature, time and pressure. Whether it is heat transfer film (HTV) , direct transfer (DTF) or sublimation transfer, it can ensure uniform heat distribution, make sure every transfer effect is perfect.

| Model | B2-N |

| Features | Electric | Swing | Slide Pro | Quick Platens | Curing |

| Voltage | 110V - 60Hz | 220V - 50Hz |

| Heat Platen | 16" x 20" | 40 x 50cm |

| Power | 1800W - 2200W |

| Controller | LCD Controller V3 |

| Max. Temp. | 232℃/450°F |

| Temp. Difference | ±4°F/2℃ |

| Power-off Preset | Max. 120 Mins |

| Max Timer Preset | 999 sec. |

| Max. Downforce | 300 g/cm² - 40 x 50cm |

| Pressure Setting | Digital Control |

| Accept Thickness | ≤4.5cm |

| Product Size | 84 x 44 x 54cm |

| Package Size | 86.5 x 54.5 x 72.5cm |

| Product Weight | 63kg |

| Shipping Weight | 68kg |

| Certificate | CE/UKCA (SGS Audited) |

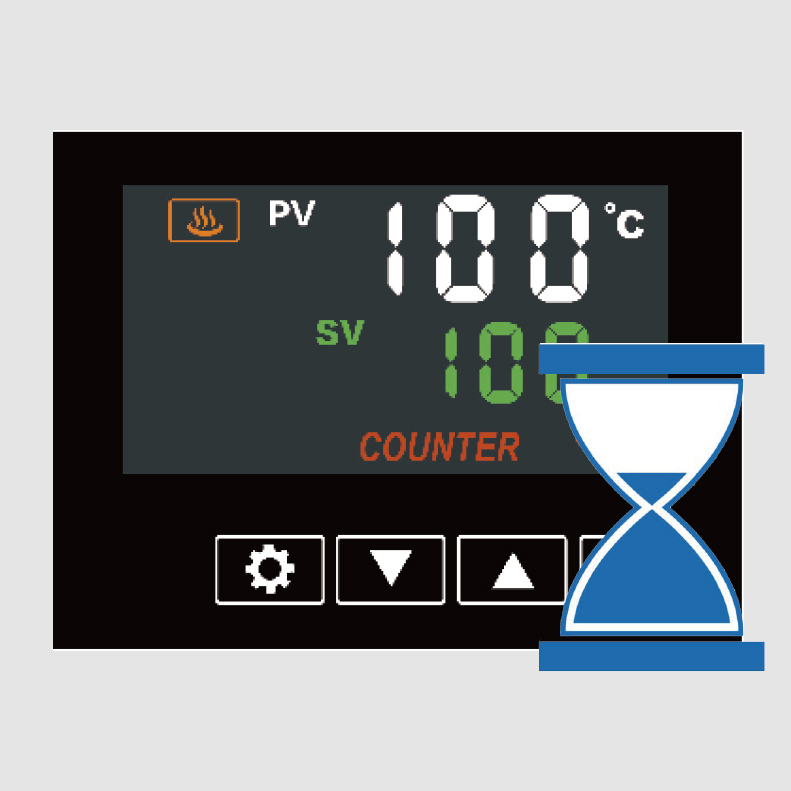

The advanced temperature control system can monitor and adjust the temperature of the heating plate in real time to ensure the temperature balance and stability of the whole transfer process, and effectively avoid the color difference or incompleted transfer caused by temperature fluctuation.

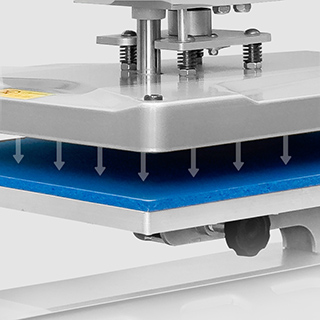

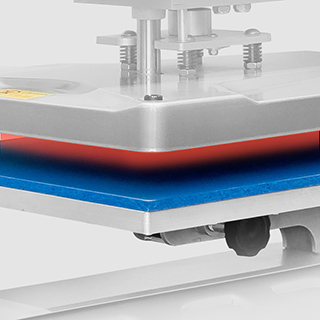

Electric drive system to achieve high-precision pressure regulation, so that the pressure throughout the large area can have a uniform distribution of the heating plate, to ensure that the pattern firmly attached to the fabric, no bubbles, no dislocation.

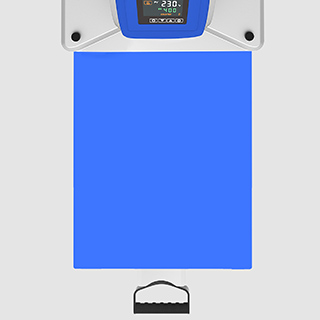

The 16 x 20 inches heating plate can fully meet the needs of large area printing, whether it is single customization order or mass production, it can significantly improve work efficiency.

LCD display shows temperature, pressure and countdown in real time. Automatic timing and safety protection function to ensure that the equipment is always run in the best condition. The machine can effectively prevent overheating, to ensure the safety of operators.

The optimized heating system can quickly reach the preset temperature in a short time, which saves energy and improves production efficiency. It is perfect for mass production and customized printing.

The 16X20 electric digital control heat press is suitable for a wide range of heat transfer needs, including but not limited to:

T-shirts and hoodies: for customization and mass production.

Handbags and aprons: ideal for promotional gifts and fashion accessories.

Canvas printing: Used for small size art reproduction and home decoration.

Other soft materials: such as pillowcases, flags and other textile transferring.

The device supports a variety of transfer materials:

Direct transfer printing (DTF) : suitable for full-color, detail-oriented design.

Thermal transfer film (HTV) : ideal for overlaying layers and personalizing text and patterns.

Sublimation transfer: suitable for polyester fabric, printing effect is bright and long-lasting.

Other special heat transferring: such as foil transferring, to meet the needs of unique effects.

Successful transfer printing requires precise control of temperature, time and pressure. The following is the basic parameters of commonly used transfer method reference

| Transfer Material | Temperature (°C) | Time (sec) | Pressure |

| Direct Transfer (DTF) | 150–165 | 10–12 | Moderate |

| Heat Transfer Film (HTV) | 150–165 | 8–12 | Moderate |

| Sublimation Transfer | 190–200 | 20–25 | Light to Moderate |

| Special Foil Transfer | 160–170 | 10–15 | Moderate |

Note: Specific parameters may be adjusted according to actual materials and design requirements. Please be sure to conduct trial printing and adjust the parameters first.

Make sure the workstation is clean and the no dust and oil on the surface of the T-shirt or other blank fabric. Select the appropriate transfer material and conduct a preliminary test to determine the best parameter settings.

Use the intuitive LCD control panel to adjust the required temperature, time and pressure. The digital control system ensures that each transfer is performed in the best condition.

Place the T-shirt flat on the heating plate and accurately align the transfer pattern. Start the machine when everything is placed well.

Pressing the start button, and the machine automatically starts the countdown program to evenly apply heat and pressure to the garment. After the transfer is completed, the heating plate will automatically lift up to prevent overheating.

After the transfer is completed, gently hold the T-shirt and carefully check the transfer effect. If necessary, adjust the parameters or make partial repress.

Check the power cord, control panel and other electrical components to ensure that the equipment is operating normally.

Use the equipment according to the operating instructions in the user manual to ensure safety and efficiency.

It is recommended to wear high-temperature resistant gloves during operation to avoid direct contact with hot surfaces.

A1: You can easily adjust the temperature, time and pressure through the LCD control panel. It is recommended to conduct a trial print before the first time use to ensure that the setting parameters meet the requirements of the transfer material used.

A2: This machine supports multiple methods such as DTF, HTV, sublimation and special foil transfer to meet various printing needs.

A3: The advanced digital control system and uniform pressure distribution design ensure consistent temperature and pressure on the entire heating plate, and high-quality transfer materials will further enhance the final effect.

A4: The equipment is equipped with automatic timing, real-time digital display and triple thermal protector protection to effectively prevent overheating and ensure the safety of the equipment and the operator.

Use a high temperature detergent and a soft cloth to clean the heating plate to remove any ink and adhesive residue from the transfer process.

Check the power cord, fuses, and control panel regularly to ensure that all electrical components are in good condition.

Lubricate the electric drive regularly to keep pressure regulation smooth.

Calibrate the temperature sensor regularly to ensure accurate temperature readings.

Strictly make routine maintenance according to the manufacturer's recommended maintenance guidelines and arrange for professional inspections when necessary.

For more product details, technical support or after-sales service, please visit our official website or contact our customer service team:

【E-mail】admin@heatpressleader.com

【WeChat | WhatsApp】+86 18659276806

【Home】www.heatpressleader.com

【Facebook】www.facebook.com/HeatPressLeader

【TikTok】www.tiktok.com/@heatpress_leader

【Instagram】www.instagram.com/heatpressleader

Choose the 16x20 Electric Digital Control Heat Press to experience the high-quality, high-efficiency solutions that Heat Press Leader brings to T-shirt printing and textile transfers. With superior technology and outstanding performance, this equipment will surely help your business move towards new success.