16x20 Automatic Electric Dual-Station Heat Press (No Air Compressor Required) Tutorial: Why Do You Need a High-Efficiency Dual-Station Heat Press?

In the fast-growing custom textile printing industry ,efficiency and quality are critical. Traditional heat presses for sale with single station have low conversion efficiency, while some pneumatic dual models require external air compressors.

Our 16x20 Automatic Electric Dual-Station Heat Press without these issues with an electric drive system—no air compressor needed. Its dual-station design allows continuous operation, support boosting productivity. Ideal for T-shirts, bags, and mass production, it ensures efficiency and precision .

This guide covers its features, specifications, applications, operation, and maintenance for seamless high-quality production.

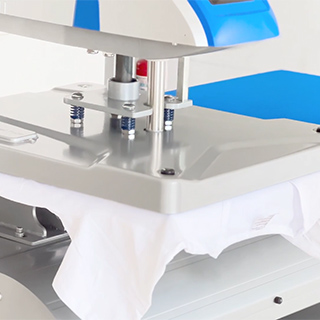

Our 16x20 Automatic Electric Dual-Station heat press is an advanced heat transfer machine designed for textile printing on many different materials, such as T-shirts, canvas bags, mouse pads etc. It’s with a dual-station alternating work mode with an automatic sliding heat platen, allowing seamless production where one station is in use while the other is being prepared.

With an electric drive system, there is no need for an air compressor, reducing operational costs and makes operation simpler and keeps the workspace cleaner.

| Model | B2-2N |

| Features | Electric | Twin Platens | Quick Platens | Curing |

| Voltage | 110V - 60Hz | 220V - 50Hz |

| Heat Platen | 16" x 20" | 40 x 50cm |

| Power | 1800W - 2200W |

| Controller | LCD Controller V3 |

| Max. Temp. | 232℃/450°F |

| Temp. Difference | ±4°F/2℃ |

| Power-off Preset | Max. 120 Mins |

| Max Timer Preset | 999 sec. |

| Max. Downforce | 300 g/cm² - 40 x 50cm |

| Pressure Setting | Digital Control |

| Accept Thickness | ≤4.5cm |

| Product Size | 91 x 57 x 70cm |

| Package Size | 110 x 83 x 87cm |

| Product Weight | 125kg |

| Shipping Weight | 140kg |

| Certificate | CE/UKCA (SGS Audited) |

1. Dual-Station Alternating Operation – Double the Efficiency Users can operate on one station while setting up the next product on the other station, eliminating idle time and improving productivity by at least 50% compared to single-station presses.

2. Electric driving System – No Air Compressor Required The smart electric drive system eliminates the need for complex pneumatic piping, reducing noise and maintenance costs and make the working environment quieter and cleaner..

3. Smart LCD Control Panel – Intuitive Operation The LCD digital control system support precise temperature, time, and pressure settings, accommodating various heat transfer processes and ensuring consistent print quality.

4. Even Pressure Distribution – Superior Transfer Quality The electric pressure system provides stable and uniform pressure, avoiding the problems of pattern falling off, blurring or unclear edges caused by uneven pressure in traditional mechanical equipment..

5. Energy Efficient – Ideal for Continuous Production Optimizing energy consumption design not only meets the needs of high-load continuous operation, but also reduces energy waste and lowers long-term operating costs.

Our 16x20 automatic heat press machine is widely applicable for various heat transfer products, including but not limited to:

Apparel Printing: T-shirts, hoodies, sportswear, work uniforms

Eco-Friendly Bag Customization: Canvas bags, shopping bags

Home Accessories: Mouse pads, cushions, aprons

Brand Promotion: Corporate T-shirts, promotional giveaways

Personalized Customization: Memorial T-shirts, fan merchandise

| Transfer Material | Temperature (°C) | Time (sec) | Pressure |

| Direct Transfer (DTF) | 150–165 | 10–12 | Moderate |

| Heat Transfer Film (HTV) | 150–165 | 8–12 | Moderate |

| Sublimation Transfer | 190–200 | 20–25 | Light to Moderate |

| Special Foil Transfer | 160–170 | 10–15 | Moderate |

Note: Specific parameters may be adjusted according to actual materials and design requirements. Please be sure to conduct trial printing and adjust the parameters first.

Step 1: Set the parameters --Adjust the temperature, time, and pressure on the LCD control panel according to transfer materials.

Step 2: Place the product -- Position the T-shirt, canvas bag, etc., on the worktable and align the design.

Step 3: Start heat pressing --Press start button ,the machine will automatically apply pressure and begin timing.

Step 4: Remove the finished product -- Once the transfer is complete, the platen will lift automatically. Remove the item and peel film to get printing result .

Step 5: Alternate workstations for continuous production --While one side is pressing, prepare the next product on the other station to maximize efficiency.

Regular Equipment Checks: Inspect power cables, control panels, and mechanical components periodically.

Follow Operating Procedures: Use the machine according to the user manual to prevent malfunctions and safety hazards.

Wear Protective Gear: Use heat-resistant gloves to avoid burns from hot surfaces.

Q1: What fabrics can this heat press handle?

A1: It works on cotton, polyester, poly-cotton blends, and more, with adjustable settings for different materials.

Q2: Does it require an external air compressor?

A2: No, it uses an electric pressure system, eliminating the need for an air compressor.

Q3: Can it run continuously for long hours?

A3: Yes, it is designed for mass production and stable long-term operation.

Q4: How to prevent blurred transfer images?

A4: Ensure even pressure distribution and adjust temperature/time based on the fabric type.

Clean the heat platen regularly --using high-temperature-resistant cleaners to remove ink and adhesive residues.

Check equipment functionality --by inspecting power cables, fuses, and control panels to avoid malfunctions.

Lubricate moving parts --periodically to ensure smooth operation and prevent wear.

Calibrate temperature sensors-- regularly to maintain accurate heat settings.

Follow manufacturer maintenance guidelines for optimal performance and extended machine lifespan.

The 16x20 Automatic Electric Dual-Station Heat Press (No Air Compressor Required) offers high efficiency, an electric pressure system, and precise temperature control, making it an ideal solution for textile printing. Whether you run a small customization shop or a large-scale production business, this machine will help you boost productivity, reduce costs, and achieve superior print quality!

For more product details, technical support or after-sales service, please visit our official website or contact our customer service team:

【E-mail】admin@heatpressleader.com

【WeChat | WhatsApp】+86 18659276806

【Home】www.heatpressleader.com

【Facebook】www.facebook.com/HeatPressLeader

【TikTok】www.tiktok.com/@heatpress_leader

【Instagram】www.instagram.com/heatpressleader